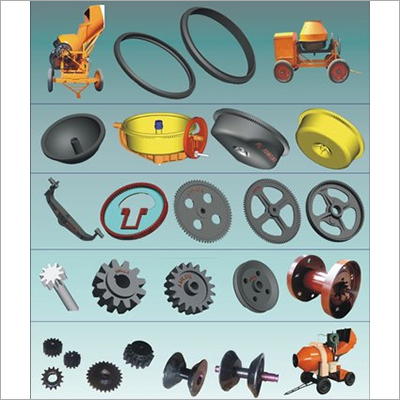

Cement Concrete Mixer Chain Wheel

Price 1000 INR/ Piece

Cement Concrete Mixer Chain Wheel Specification

- Diameter

- 6 to 24 inches (varies by application)

- Size

- Custom/Standard

- Noise Level

- Low

- Surface Finish

- Smooth/Polished

- Drive Type

- Chain Drive

- Lubricating System

- Manual/Greased

- Capacity

- Depends on Mixer Model

- Features

- High tensile strength, Corrosion resistance, Durable

- Shape

- Round

- Usage & Applications

- FOR Construction Machine

- Technology

- Casting

- Power Source

- Manual

- Surface Treatment

- Galvanized

- Dimension (L*W*H)

- As per model/specification

- Weight

- Approx. 2-8 kg (varies by model)

- Color

- Silver/Grey

Cement Concrete Mixer Chain Wheel Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- All India

About Cement Concrete Mixer Chain Wheel

Versatile Compatibility and Customization

Designed to integrate seamlessly with all standard cement concrete mixers, the chain wheel can be tailored in terms of size, teeth, and dimensions to match specific construction machine models. This adaptability ensures optimal performance and ease of installation across various applications in the construction industry.

Durable and Precision-Engineered

Using durable steel and advanced precision machining, this chain wheel boasts high tensile strength, excellent corrosion resistance, and a robust finish. The galvanized surface enhances longevity while maintaining a smooth, polished appearance. It can withstand rigorous job site conditions, serving reliably in both manual and hoist-operated systems.

FAQs of Cement Concrete Mixer Chain Wheel:

Q: How do I determine the correct number of teeth for my Cement Concrete Mixer Chain Wheel?

A: The number of teeth required for your chain wheel is based on your specific mixer model and operational requirements. You can provide your specifications, and the manufacturer will customize the chain wheel accordingly to ensure seamless compatibility and maximum efficiency.Q: What is the process for installing the chain wheel on my construction machine?

A: Installation involves aligning the chain wheel with the mixers drive system, securing it with appropriate fasteners, and connecting the chain drive. Its recommended to consult your machines manual or seek assistance from a qualified technician to ensure proper fitting and operation.Q: When should I consider replacing the chain wheel on my concrete mixer?

A: Replace the chain wheel if you notice excessive wear, damage, or if it affects the smooth operation of the mixer. Routine inspections can help detect early signs of wear and prevent potential breakdowns during critical phases of construction work.Q: Where can the Cement Concrete Mixer Chain Wheel be used?

A: This chain wheel is suitable for all standard cement concrete mixers, commonly deployed on construction sites and infrastructure projects. Its robust construction makes it ideal for environments where durability and reliability are crucial.Q: What are the main benefits of using a precision machined, galvanized steel chain wheel in construction machines?

A: Precision machining and galvanization provide enhanced strength, corrosion resistance, and durability, resulting in low maintenance, a smooth finish, and long service life. This ensures consistent performance even under demanding conditions.Q: How should I maintain the chain wheel to ensure optimal performance?

A: The chain wheel requires minimal maintenance. Regular manual lubrication or greasing, combined with periodic inspections for wear or damage, will help maintain smooth operation and extend its lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

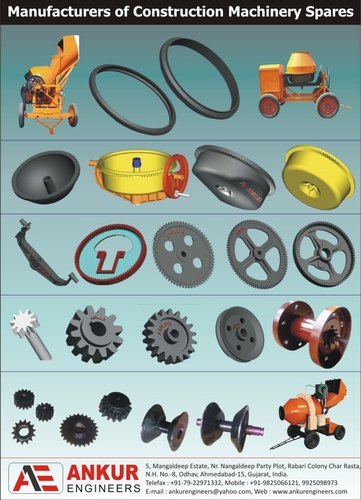

More Products in Concrete Mixer Machine Spare Parts Category

Cement Mixer Machine Spare Parts

Price 30000.00 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Cast Iron, Mild Steel, Alloy Steel

Product Type : Other, Cement Mixer Machine Spare Parts

Surface Finish : Smooth, Anticorrosive

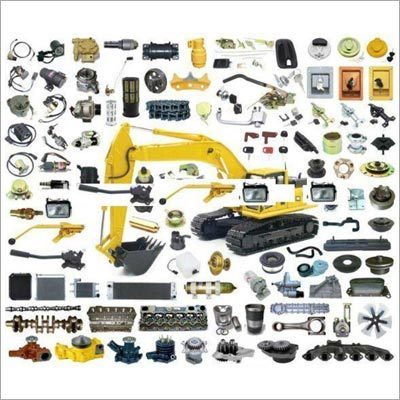

Construction machinery Spare Parts

Price 30000.0 INR / Unit

Minimum Order Quantity : 5 Units

Material : Forged Steel / High Strength Alloy Steel

Product Type : Other, Construction Machinery Spare Parts

Surface Finish : Smooth, Corrosion Resistant

Concrete Mixer Machine Spare Parts

Price 30000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Steel

General Use : FOR Construction Machine

Product Type : Machine Spare Parts

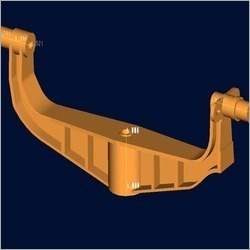

yoke for concrete mixer machine

Price 10000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Steel

General Use : FOR Construction Machine

Product Type : Mixer Machine Spare Part

Send Inquiry

Send Inquiry